When refinishing a bathtub or tile it is important to follow the coating manufacturer specifications on how thick to apply your coating. It’s not just a matter of applying the coating until it looks “good enough”; it’s a matter of applying the coating until the specifications are met for optimal performance. If you do not follow this rule, you are setting yourself up for a wide range of bathtub reglazing problems.

When your bathtub and tile reglazing coating is applied at the appropriate thickness, the physical and protective properties of the coating material are optimized. When you apply your bathtub and tile resurfacing coatings outside of the specified range, there are a number of problems that can occur.

Below are a few common bathtub reglazing problems that may occur.

Insufficient Coating Thickness

Insufficient coating thickness in short is “not applying enough”. The goal here is the protection of the substrate and when you don’t apply enough coating, the resulting “dry film thickness” is not achieved therefore resulting in a performance threshold that is below the acceptable level. Several bathtub reglazing problems can occur when the coating film is applied at a range below the recommended thickness range:

Brittleness of Coating

When you don’t apply enough coating for glazing tubs, the physical properties are jeopardized and this can cause the coating to become brittle which in return will result in cracking and delamination.

Visibility of Substrate

When you don’t apply enough coating, the underlying substrate may be visible. How can this cause a problem? Let’s say you apply your coating over the top of an epoxy coating, the epoxy coating could be susceptible to chalking from exposure to light and this in turn could cause blotchiness and result in a shorter coating lifespan.

Excessive Coating Thickness

Often, refinishers think it is ok to just spray on what they have left in their container believing that they are just increasing the protection of the substrate. This is not true. In fact, more is not better and can lead to several modes of DIY reglazing bathtub failure. Here are a few...

Runs and Sags

If you apply too much coating, it will run or sag on a vertical surface. When the coating sags, it creates an uneven film surface which creates excess buildup in the sag areas and insufficient thickness in the non-sag areas. The insufficient thickness can cause what has been discussed above in “INSUFFICIENT COATING THICKNESS”.

Cracking and Delamination

When coatings are applied at thicknesses above specification it often results in cracking which in turn results in delamination.

Increased Dry Time

Dry and cure time is directly related to thickness. If you apply your coating too thick when glazing tubs, it delays the dry time and results in debris pick-up and this in turn results in a bad appearance.

Improper Curing

Coatings that are applied too thick don’t cure properly. This can result in a fixture that is put into service before it is cured and ultimately cause damage.

Wrinkling

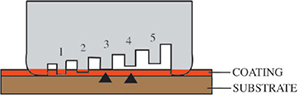

Too much coating can cause wrinkling. This means the top layer (skin) of the coating dries but the coating below the skin remains soft (uncured) due to less exposure to the atmosphere. When this happens, surface movement causes ridges & valleys in the coating known as wrinkling.

Prevent Common Bathtub Reglazing Problems by Measuring Your Coating Thickness

Measure your coating thickness with a “Wet Film Thickness Gauge”. You will need to communicate with your bathtub refinishing paint manufacturer to get the wet film thickness specification for your particular coating and if you have a technical data sheet for your product the information should be there.

It may sound like a lot, but when you first start out DIY reglazing bathtubs; it is good practice to get to know your coating and its limitations. This does not mean that you have to do it forever but in the beginning it's better to be safe than sorry. Just like everything else, the more you refinish, the better you get. After a while, you will figure out exactly how much coating to use and how many coats it takes to achieve the specified coating thickness.

Learn More About Glazing Tubs

The above are common examples of what can happen when you apply your bathtub and tile refinishing coating outside the specified range. If you do not follow the rules and experience a performance issue, you need to consider whether or not you followed the manufacturer’s recommendations for thickness. Be objective when performing an investigation for failure and look at all the facts. If you find that coating thickness standards have been followed, look into preparation. You can read a great article here about bathtub and tile refinishing preparation and coating failures.