Coatings that are applied to improperly prepared bathtub and tile surfaces usually result in one thing: FAILURE. The question is, was this failure the result of an improperly cleaned surface? Was there a contaminant left on the surface? Was there moisture left on the surface? Or was the new coating painted over the top of an existing coating that was already failing?

Surface preparation is one of the most important steps for tile and bathtub surface refinishing. The purpose of surface preparation is to clean the surface and get the surface ready according to your coating manufacturer specifications.

When selecting a bathtub and tile refinishing coating manufacturer, it is critical that you follow their specifications to the “T” and use a system that is properly matched like the Topkote Reglazing System for proper DIY bathtub refinishing. If you wander outside the reservation, your coating may not achieve the adhesion needed to perform as intended. When it comes to bathtub refinishing prep, a failure to follow the specifications of your coating manufacturer is considered to be an expected premature coating failure.

When preparing a surface, various methods are used to ensure the surface is prepared to the specifications set forth by your coatings manufacturer. Surface preparation methods include stripping, hand/power tool sanding, etching and degreasing. The degree of surface preparation is dependent on the existing bathtub or tile surface and the coating system you intend to use.

For example, a tub that has been previously refinished like the one in Figure 1 shows signs of existing coating failure. In this scenario, the proper surface preparation method would be to remove the existing coating by means of a chemical remover, use a power tool sander to remove any residual coating not removed by the chemical stripper, degrease the surface, prime the surface using an adhesion promoter such as Topkote’s Crosslink III and apply finish.

Figure 1: Coating Failure Due to Improper Surface Preparation.

When cleaning, it is important that any “interference” material be removed from the surface or the coating may not properly adhere to the substrate. Grease, oil, dirt and existing coating that is failing are obvious interference materials. Less obvious contaminants may not even be visible, such as silicone or chalking.

Bathtub Resurfacing Warning Signs

Here are more examples and bathtub resurfacing warnings that will help bring this topic into focus:

DIY Bathtub Refinishing on Top of a Pre-Existing Coating That is Failing

In a case where the surface was previously refinished, like in Figure 1, the refinisher simply feather sanded around the failed area, cleaned the surface and refinished over the top. In this scenario, the coating will likely fail. Why? The existing coating had poor adhesion to begin with and the new finish will likely delaminate along with the old finish at some point and result in a FAILURE. The existing finish should have been removed.

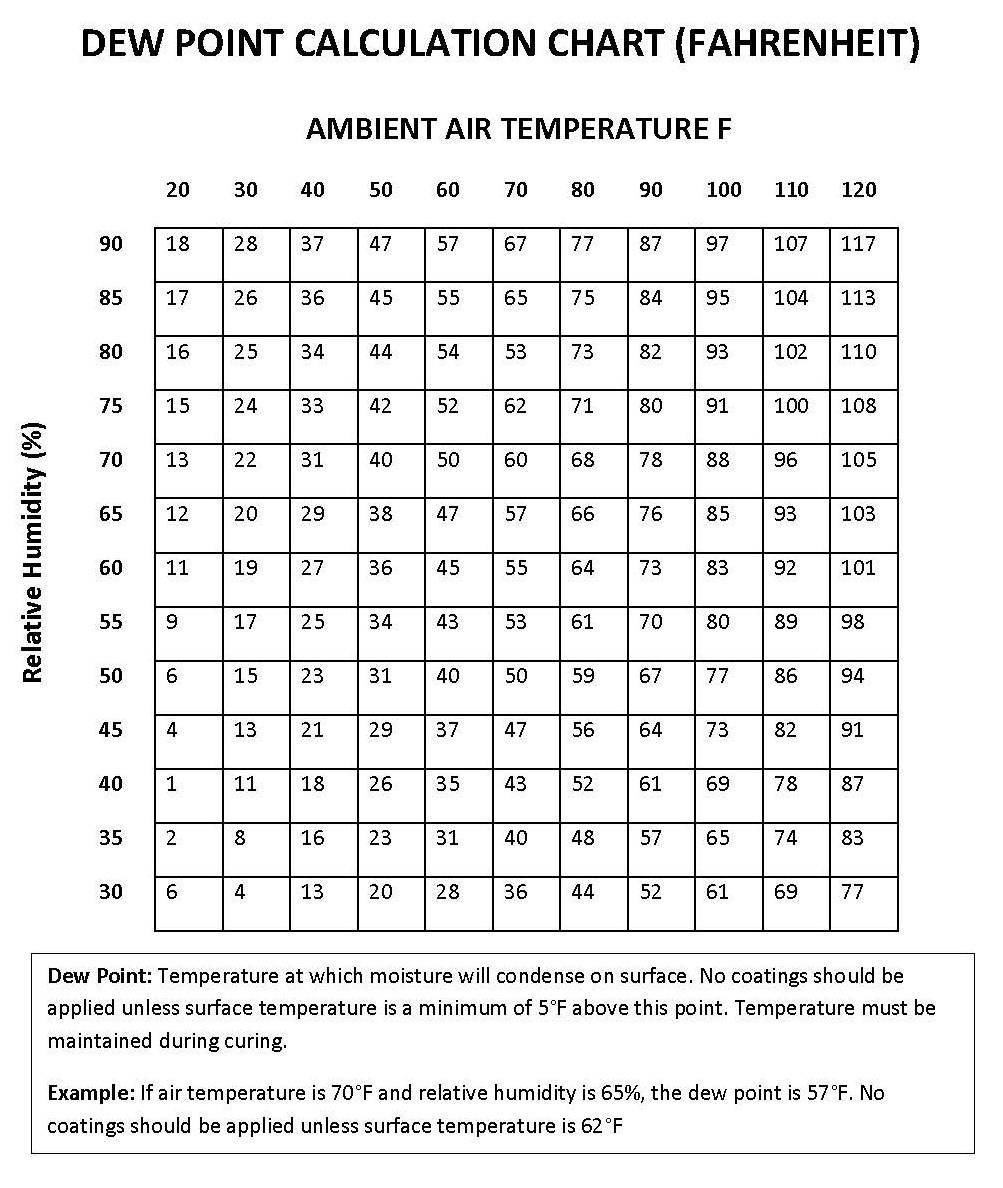

Dew Point Surface Moisture

The tile or bathtub refinishing prep has been done correctly, but there is microscopic moisture on the surface. This microscopic moisture will not allow the coating to adhere properly which will likely result in a FAILURE. This microscopic moisture is caused by temperature and humidity, and there is a point at which moisture will condense on the surface called Dew Point. No coating should be applied unless the surface temperature is a minimum of 5°F above the Dew Point.

Example: If the air temperature is 70°F and relative humidity is 65%, the dew point is 57°F. No coatings should be applied unless the surface temperature is 62°F. What should be done? A simple tool such as an infrared thermometer (available at Harbor Freight) can give you an idea what temp the surface is. If the temp is below what it should be, you can bring it up by using a heat gun (also available at Harbor Freight). You can also use a solvent such as acetone to remove surface moisture; however, it will also bring down the surface temp. Refer to the handy Dew Point chart below.

Chalking from Acid Etching

In this case of DIY bathtub refinishing, the refinisher used an acid etch (hydrofluoric acid) to remove the gloss from the bathtub. This is done to give the tub a proper profile to achieve a mechanical bond when using the etch & epoxy bathtub refinishing system. When it came time to remove the etch from the surface, the refinisher simply scrubbed with a scotch bright pad, rinsed the surface with water, dried & tacked the surface, primed using an epoxy primer and finished. Problem: chalking will occur on the surface from etching and create a barrier which will prevent the coating from adhering and result in a FAILURE. Solution: The surface should have been wet sanded after the initial rinse, then rinsed again.

Nowadays, refinishers are turning to the less hassle, no-etch, adhesion promoter method of refinishing like Topkote’s Reglazing System. With this method of bathtub surface refinishing, you skip the nasty acid etch process which saves time, and after all, time is money!

Why It's Important to Avoid Mistakes During DIY Bathtub Refinishing

The examples above show the importance of bathtub refinishing prep for all surface areas. If the surface is not properly prepared and you are not using a properly matched coating system, you will surely invite a coating FAILURE. The last thing that you want is to waste time, money and energy on a bathtub that you're truly unsatisfied with. That's why you need to invest in a bathtub refinishing kit from Topkote. If you're ready to get started with your bathtub surface refinishing project, contact us today and we'll be happy to help!

Purchase Your Refinishing Kit Today!

Start refinishing your bathtub with our kits available at Topkote!

Shop Bathtub Refinishing Kits